|

|

|

|

|

|

|

Digital Command Control (DCC)

|

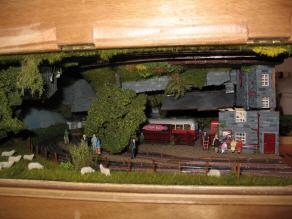

"Botwm Bach" Live Steam Layout

|

|

|

|

|

|

|

|

|

Auf Flagge ---> klicken: Zur deutschen Version!

|

|

|

|

|

|

|

|

|

Botwm Bach = cymreig for "Little Button"

|

|

Model Railway - everywhere!

|

|

Inserts in picture above:

|

Left: Ready for Transport!

Right: Hand Baggage in the Airplane

|

Video-Link

|

Now even double-headed trains in Botwm Bach!

Look here for a small video to get a first impression of the small layout.

|

History - Beginnings

|

At an exhibition in Porthmadog/Wales in 1999 I became aquainted with Brian Caton, a very experienced english railway modeller. He had his stand with his tiny live steam products next to my WEK model railway layout. After a short time I had the irresistible idea of operating a model railway layout with such a locomotive everywhere and independent from any mains supply.

Because of the quite substantial price of such a loco it took until after my return home for my decision to purchase one from Brian. It had then been made to order with individual livery, lining and etched name- and numberplates.

It was obvious - although this engine is able to run on every 009 or H0e layout - that an individual, small and easily portable layout had to be created, which should provide for a continuous run for the engine.

|

The Live Steam Engine

|

The 009 locomotive

(4mm scale, gauge 9mm)

after its integration into the WEK's fleet

|

|

|

Click on pictures to enlarge!

|

|

|

The new loco on the WEK layout, leaving the Heikeberg tunnel.

|

|

|

|

|

Technology of the Engine

|

|

|

|

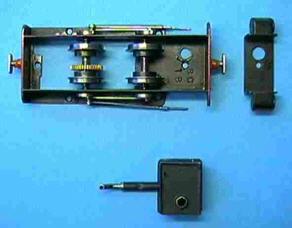

Loco chassis with burner (in front) and the dummy cylinders (right)

.

|

|

|

Click on pictures to enlarge!

|

|

|

The steam engine with boiler and driving gearwheel.

|

|

|

|

|

The fine superheater tube visible from underneath.

|

|

|

|

|

|

The steam engnie from underneath, flywheel on left and crank on right. The excenter for the piston valve is in the middle.

|

|

|

|

|

View from left/behind

|

|

|

|

|

|

View from behind

|

|

|

Click on pictures to enlarge!

|

|

Top of Page

|

Homepage - English

|

|

|

|

|

|

|

|

Engineering - Locomotive

|

The mature design of the engine impresses with a very clean operation (superheated boiler) and can be operated on any model railway layout without the danger of staining the scenery. The loco is fired with ethanol (96%, from the chemists) and drives 8 to 10 minutes and approx. 100 yards with just 0.6 ccm of fuel and 1.2 ccm of demineralised water.

The driving power is created by a standing steam engine in the cab with piston valve. It transmits its high-speed power via multiple gears to the driving wheels. This results in a prototypical slow, steady and powerful performance of the engine. It can haul substantial trains, even on gradients. The piston valve is actuated by a slip excenter, which allows for operatoin in both directions, dependent on the push with that the engine is being started after a three-minute heating-up.

If the boiler pressure gets too high (if one omits to start the engine with a push after firing) it is released by a safety valve, made from a silicone sleeve on a small tube. The exhaust steam leaves the engine by the chimney, not always very visible due to the superheating. The outside cylinders are only dummys. The power from the driving axle is transmitted to the front wheels via the con rods.

|

Construction - Layout

|

First Inspirations

Picture on right:

Hans Schellenberg with his suitcase layout

Scale H0e, 3,5 mm, gauge 9mm

|

|

|

|

Click on pictures to enlarge!

|

Already in 1987 I became aquainted with Deutsche Reichsbahn railwayman Hans Schellenberg of Zschopau (East Germany, then GDR). In uncounted standby duty hours he created a foldable micro layout from an old wooden suitcase. It allows for instant model railway operation almost everywhere.

This gave me inspiration for my new modelling project.

|

|

|

|

|

|

The closed suitcase of my new model railway layout.

Measurements (closed):

56 x 41 x 21 (cm)

22" x 16" x 8 1/4" (approx.)

|

|

|

|

"Trackplan" of the opened layout.

When in operational condition, the scenic area is 54 cm x 80 cm

(approx. 1' 9 1/4" x 2' 7 1/2").

Trackwork is Peco "crazy sleeper" 009 flexible track, minimum radius 8". Points are also Peco 009 (one right, one Y-point).

Both points are operated from the rear of the layout by the wire-in-tube method.

|

|

|

|

|

|

The suitcase has several small conmpartments for the engine, fuel, water and servicing items as well as mains leads.

The layout can also be operated electrically, it has got a mains plug built into its case. An integrated transformer provides for the power supply for the Gaugemaster controller.

|

|

|

|

|

The controller is in a drawer on the side of the suitcase, which also ...

|

|

|

Click on pictures to enlarge!

|

|

|

... provides space for the rolling stock. Stock is being safely protected with strips of rubber foam.

|

|

|

|

The closed drawer for rolling stock and controller.

When the suitcase is closed, the drawer is protected by the rim of the bottom lid (see picture below).

|

|

|

|

|

|

The levers for point operation at the rear of the suitcase.

The wires are attached at the bottom of the rockers.

|

|

|

|

|

The wooden buttons for point operation on the outside of the case, which ...

|

|

|

Click on pictures to enlarge!

|

|

|

... are protected by the closed bottom lid, just like the stock drawer.

|

|

|

|

View from underneath into the folded layout.

The point levers on right, on left the contacts which connect both halves of the suitcase electrically (phosphor bronce strips).

It is also visible, how the scenery structures fit into each other when folding the case down.

|

|

|

|

|

|

By a special design the front hinge of the suitcase is hidden from view.

The station building (shown here with its wooden substructure) stands above the parting point above the hinge. The roof swings aside, thus releasing the hinge for movement.

|

|

|

|

|

Station building with roof closed

|

|

|

Click on pictures to enlarge!

|

|

|

During opening ...

|

|

|

|

... and fully opened.

The hinge is now clearly visible and ...

|

|

|

|

|

|

... the suitcase can be folded.

By this action the station building is being "split".

|

|

|

|

|

When folding the suitcase is completed, the station roof is fixed by the road surface above, preventing it from rattling during transit.

|

|

|

Click on pictures to enlarge!

|

|

|

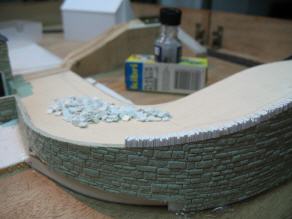

The base of the scenery is made of expanded polystyrene, cut and formed with a heated wire.

|

|

|

|

The copestones on the dry stone walls are fixed individually (pieces cut from polystyrene strip).

The walls (also those of the buldings) have been made from Wills polystyrene sheet.

|

|

|

|

Click on pictures to enlarge!

|

|

Top of Page

|

Homepage - English

|

|

|

|

|

|

|

|

Scenery

|

Fitting the engine and for its 4mm-scale, it was obvious that a theme had to be found for the layout to represent characteristic features of my favourite holiday location North Wales.

This also gave reason for the name: It is derived from my family name "Knopf", which translates "Button" in english and "Botwm" in Cymreig.

Picture on right:

In a deserted welsh slate quarry

|

|

|

|

Click on pictures to enlarge!

|

|

Typical for North Wales is the ubiquitious slate. There is also much dry stone walling and sheep, exceeding humans by number (as is in Botwm Bach!).

|

|

|

|

|

In addition there's the special design of buildings with their prototypical chimneys and outside plumbing.

|

|

|

|

|

|

So on an area of less than 5 square feet a typical welsh scenery was created, with a station building, semi-detached cottage, dry stone walls, sheep and the remains of an abandoned slate quarry - and a narrow gauge railway of course!

(Photo: Dirk Schambach)

|

|

|

|

|

The station building with a vintage "Ffestiniog Toy Railway" poster and passengers waiting for the train.

|

|

|

Click on pictures to enlarge!

|

|

|

Convertible weather! The ideal vehicle for small welsh country lanes, which are lined with dry stone walls and hedges rather than crash barriers.

|

|

|

|

|

The PW gang cares for uninterrupted train operation.

|

|

|

|

|

|

The bus on the station yard is waiting for interchanging passengers.

|

|

|

|

|

The quiet village lane of Botwm Bach.

|

|

|

Click on pictures to enlarge!

|

|

|

Remains of an old slate quarry, whose waste tip reached to the railway's level crossing with its typical gates.

|

|

|

|

|

Top of Page

|

Homepage - English

|

|

|

|

|

|

|

|

Operation

|

The layout can be operated almost everywhere, as it doesn't need mains supply. It is especially welcome as an extra perfomrance in the pub after a long exhibition day!

Train operation is especially relaxing, as after having started the loco the operator can lean back and watch the train go round and round, being able to chat to enthusiasts on end (until the water in the boiler has been steamed away).

|

|

|

Click on pictures to enlarge!

|

|

|

In an IC Express train of German Railways DB - on the way to an exhibition: Steam trains at a speed of 100 mph!

The little boy was very lucky that there are steam locos with a modern express train - in contrary to his mother's statement a few minutes ago!

|

|

|

|

|

Steam operation in a vintage saloon carriage of the DB "Blauer Enzian" express train.

|

|

|

|

|

|

At the gala of the Brohltalbahn the layout was operated even in the open, at Burgbrohl station.

|

|

|

|

Especially on large modular layouts the small engine can demstrate its capabilities. On such a layout it travelled more than 140 yds with one firing!

An important property of the superheated steam engine is that it doesn't cause pollution on the layout. The dripping of usual steam models is unknown to her.

However, the remaining operation of the whole layout has to be stopped for the steam engine, as this has no insulated wheelsets. A simultaneous electrical operation is therefore impossible.

|

|

|

|

|

|

At the Warley Show in Birmingham. In 2013 this was the first public performance of the finished layout, after having been operated without scenery for several years.

Extremely convenient: The ultra-speedy erection and dismantling procedure and the easy conveyance - also in a train, airplane, bus and other public transport.

(By the way: 2nd spectator from left is Pete Wilson, creator of the famous slate quarry layout "Chwarel-Cwm-Bach")

|

Click on pictures to enlarge!

.

|

|

|

Top of Page

|

Homepage - English

|

|

|

|

|

|

|

|

To Other English Pages:

|

|

|