The hard-working turntable man was the first animated figure on the WEK.

The crank bears a small tube, to which both hands and forearms of the worker are soldered. The upper arms are formed by a U-shaped wire, that goes through a bore-hole in the shoulders.

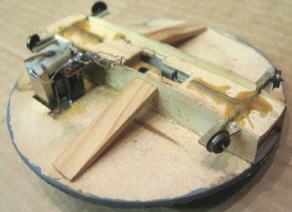

Picture: Cap of crank gear removed

|

|

|

|

click for larger pictures !

|

Fore- and upper arms are connected by a small piece of insulating tube (from the usual stranded wire for model railways).

This enables the elbows to move.

|

The man is not glued to the turntable. A small wire in his right shoe is pinned through the turntable's floor, leaving some flexibility to allow the worker to move back and forth with his whole body. This looks rather powerful!

|

|

|

|

|

The worm shaft is driven by a separate motor (Mabuchi), that is mounted upright under the turntable's floor. Wenn the cap covers the worm gear, the movement of this shaft is hardly visible.

|

|

|

|

The motor gets his supply via wipers, that run on copper clad rings in the turntable pit (see picture on right).

The current supply for the worker's motor is switched together with the drive of the turntable itself. So crank movement changes direction together with the turntable's movement.

|

|

|

|

click for larger pictures !

|

|

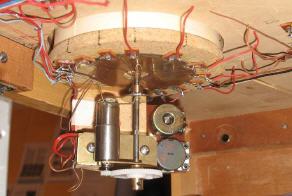

The turntable's platform from underneath.

The current wipers attached to the worker's motor are clearly visible.

The two wipers in the center near the axle bush provide the current supply for the turntable track.

The turntable has been scratchbuilt long ago for a former layout and was designed as a plate-girder turntable with a deep concrete well. After installation of the "personnel" the well was covered with the wooden floor and the dummy wheels. This conceals the drive motor of the worker and its installations.

|

|

|

|

Another detailed view of the personnel's drive.

I used a simple Mabuchi motor left over from the coreless remotoring of an engine (Liliput 2095).

The worm gear at the crank is covered with a small tin plate cap.

|

|

|

|

click for larger pictures !

|

|

The drive of the turntable from underneath. I installed a coreless motor with reduction gears (approx. 1:1200) , that drives the main shaft of the turntable via another 1:5 gearwheels.

The contact wipers that switch the shed roads are clearly visible.

On the right are the potentiometers for adjusting the speed of both the turntable and its worker.

|

|

|

|

Top of Page

Back to Selection "Moving Folks"

Back to Staff Page

|

Homepage - English

|